The SIF is a stress raiser that once applied to the calculated stress range causes failure in the component at the same number of cycles as a straight pipe with butt welded joints. Items highlighted in Blue are information from drawing.

Flanges Asme B16 5 Inch Dimensions Weld Neck Stud Bolts Class 150

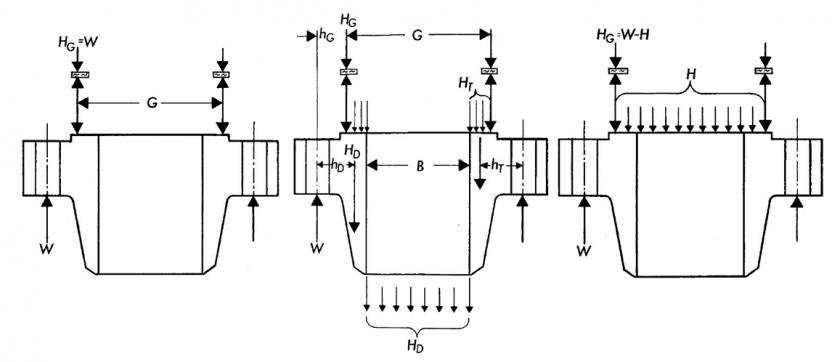

With flange dimensions calculate the shape constants and read appropriate factors from the curves or calculate using equations.

. The concentration of the me - dium has also to be entered. Allowable stress at atmospheric temp. Of bolts Fillet size 8 mm BCD C 650 2 x 8 2 2381 OD of flange A 725 2 x 2381 Width of gasket Gasket OD Gasket ID Minimum spacing of bolts 725 mm 775 mm 20 mm 690 mm 650 mm 5239 mm.

Were here to help with your flange needs. Non-standard flange is a kind of flange relative to the national standard or some foreign standards. Flange qualified for B313 service per 30451 b using ASME BPVC Section VIII Division 1 App2.

Because the standard flange can not meet the requirements of use in some special occasions it is necessary to transform and improve some standard flanges. Non-standard flange is produced and there are requirements in the design. The principal design code for the establishment of pipeline and piping flange stresses is ASME VIII Division 1 Appendices 2 P and S which forms the basis for the calculations in the flanges calculator.

However a separate analysis for the non standard flange can be performed using the component design option and designing a custom flange. Non-standard flanges are designed and calculated according to asme viii div1 appendix 2 and appendix s and according to asme viii div2 part 416. Alternatively flange may be qualified for B313 per 30472 a extensive successful service.

The non standard flange design automation program is written in Auto LISP language compatible with AutoCAD. Inside Diameter B 1600 Outside Diameter A 22 Thickness t 175 Hub radius r 0375 Pipe thickness g0 075. Universal engine which allows to add any new algorithms without breaching the programs operational logic.

I suggest you make one your own so you understand what youre calculating. 2 for the design of non-standard flanges without flat gaskets the influence of external loads on bolts and flange moments can be dealt with based on asme vim-2 2019. 32 bolt characteristics this area.

Internal design pressure P. In the Body Flange Dialog there is a Button to retrieve the dimensions of a Standard Flange see below. Non ASME standard flange design.

For both standard and non-standard flanges. Ad We provide ANSI API and AWWA pipe flanges in carbon steel stainless steel alloys. Items highlighted in Orange are information estimated by engineer.

2 For the design of non-standard flanges without flat gaskets the influence of external loads on bolts and flange moments can be dealt with based on ASME VIm-2 2019. Let us look at Markls definition of SIF closely. Calculate all flange loads moment arms and moments for both gasket seating and operating conditions.

Allowable stress at design temp. Gasket OD 1775 Gasket ID 1625 Gasket m 3 Gasket y 10000. Modulus of elasticity at design temp.

Torque calculations are based on the simplified formula explained in the current version of. Modulus of elasticity at atmospheric temp. 16 Bolts x 1 dia on a 2025 BCD C r.

Welcome to this interactive flange bolting calculator from HYTORCThe program computes recommended torque values bolting patterns tool selection and pump pressure settings for standard ASME B165 and API 6A flanges under normal assembly conditions. In many cases the chemical formula is shown automatically. Non standard ASME Flange Design Calculations Excel sheet for Pressure Vessel.

32 Bolt characteristics This area displays information con - cerning the bolts of the flange. SnTMan Mechanical 4 Apr 18 1419. Use this to calculate the appropriate bolt area and get a reasonable size for the flange.

Concept of program operation Four primary rules of program construction have been adopted. Root diameter d b. We have to proceed a design calculations as per ASME code Section VIII Division 1-Mandatory Appendix 2 Rules for Bolted Flange Connections with Ring Type Gaskets about 10 pages of detailed calculations per flange integral loose and optional type and blind flange shall be carried out in accordance with ASME UG-346 6 pages.

Note not a better flange but a cheaper one. Number size and type of bolt The number and size of the bolts is given when using. Select M20 x 24 No.

Diameter of Flange inches No. Waters method is established on the basis of online elastic plate and shell theory of non-standard flange design calculation method whether it is internal pressure flange or external pressure flange in addition to the flange moment calculation formula is different according to the flange ring and cylinder or including tapered neck connected to the degree. Diameter of Bolts inches Bolt Circle inches 14.

Otherwise buy apiece of software provided you bought and read the Code. For Non-Standard Flanges. Dear Ali The application of weldoverlay non standard flange for highly corrosive environment is impressive but pre-clad dimensions offered by cladding vendors are differing a lot from vendor to.

Smaller bolt diameters will indeed generally yield a smaller more compact flange it is generally preferred. API ANSI BS and MSS standard pipeline and piping flanges ranging from ½ inch to 48 inch and an independent. Universal user interface which changes only if there are differences in particular calculation standards.

ASME B313 SIFs are based on A R C Markls results of a series of fatigue tests carried out in the 1950s. The flange calculator includes a database of 600. Most true flange design programs will start with a small bolt typically 34 and determine whether a sufficient.

Texas Flange has been in the business of prec. Introduction of non-standard flanges.

Ms Beam Weight Calculation Formula I Beam Weight Calculator Beams

Appendix 2 Asme B16 5 16 47 Flange Design Codeware

Non Standard Flanges Asme Viii Arveng Training Engineering

Flange Calculations According To En 1591 1 Youtube

The Scope Of Asme B31 4 Design Code Engineering Blog Coding Process Engineering Engineering

Non Standard Flanges Asme Viii Arveng Training Engineering

11 How To Design Nonstandard Flanges On Standard Nozzles Autopipe Wiki Autopipe Bentley Communities

0 comments

Post a Comment